V8 型椭圆印花机创新性的采用钢架一体成型,后经CNC铣平、加工、钻孔,比传统铝架结构坚固300%以上,有效寿命可达10年以上,为精确的印花质量提供了坚实的基础。

全自动网框抬升系统,一键抬起和降低网框,使原本复杂的擦网工作变得简单而轻松,大大降低工人操作工序,提升生产效率;印头斜拉臂受力更靠前,印刷时布片前端和布片后端受力更均匀,不易出现印刷时的阴阳版,也就是通常说的前重后轻的印花效果,提升印花品质。

行业领先的印头多功能操作面板,除了控制印头手动操作、前进、后退、运行、停止、锁网以外,还可以控制机头的印刷次数、印刷速度、回墨速度等重要操作,使印花师傅在做印花效果时,无需来回于控制台和印头之间,以20色机为例,控制台和最远印头距离来回长达40米以上,提升效率尤为明显。

先进且符合工程力学结构的台板支撑系统,比传统矩形铝型材钢性提升150%以上,使得在印刷时,变形更少,不易跑位,印刷精准度比传统结构大大提高。

台板传动采用无链条机构,进口精密滚柱减速机,设备性能稳定可靠,平均无故障时间达3万小时以上。

The V8 oval printing machine adopts integrated steel frame for forming in an innovative manner and receives milling, processing and drilling with CNC. It is 300% stronger than conventional aluminum frame structure and has an effective service life of more than 10 years, thus laying a solid foundation for precise printing quality.

Fully automatic frame lifting system allows the lifting and lowering of the frame with one key, making originally complicated frame cleaning much easier and simpler, significantly reducing manual operation steps, and improving production efficiency; the cable-stayed arm of the printing head may undergo much forward force. Therefore, in printing, the front and rear ends of the cloth may undergo more uniform force, thus avoiding the uneven pattern, so called unbalanced printing effect, and improving the printing quality.

It has an industrially leading multifunctional operation panel for printing head. In addition to control of manual operations of printing head, including forward, backward, operation, stop and locking, it may also control such important operations of the printing head as printing times, printing speed and ink reclaim speed, allowing the printing operator to avoid travel to and from between the console and the printing head in making printing effect. Let’s take 20-color printing machine as an example. The distance for traveling to and from between the console and the farthest printing head is more than 40m, significantly improving the efficiency.

It has a state-of-the-art table supporting system that meeting engineering mechanic structure, which has rigidity 150% higher than conventional rectangular aluminum section, making less deformation and less displacement in printing. Therefore, its printing precision is greatly improved than conventional structure.

Table transmission is realized through the chainless mechanism. Imported precision roller reducer is adopted to ensure stable and reliable performance of the equipment with more than 30,000 hours of MTBF.

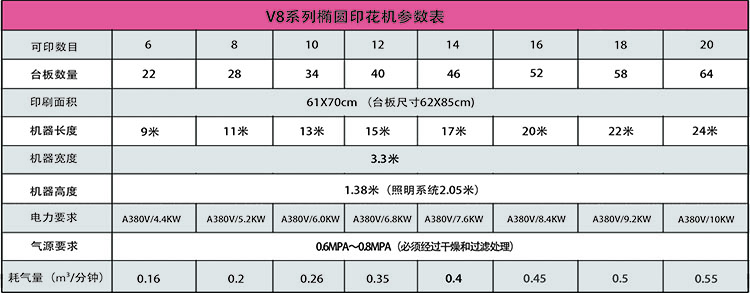

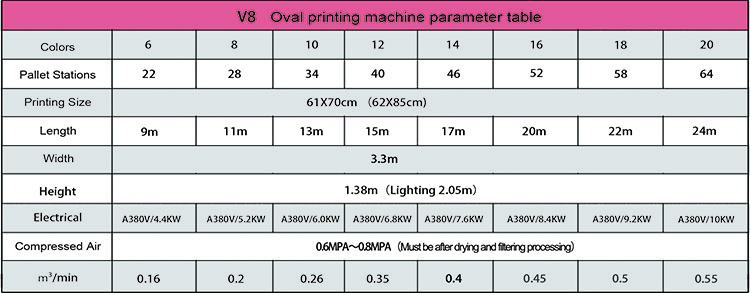

|